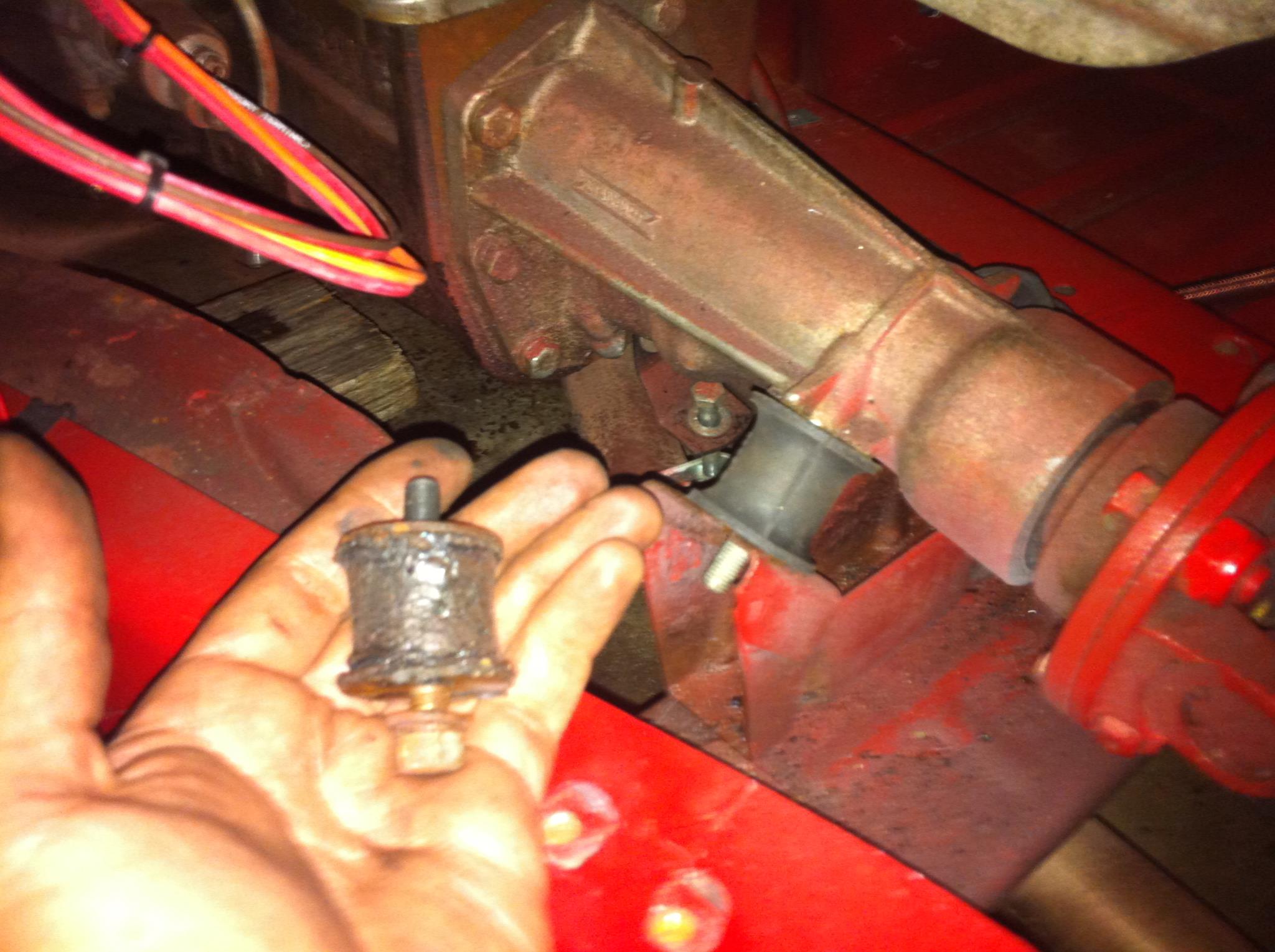

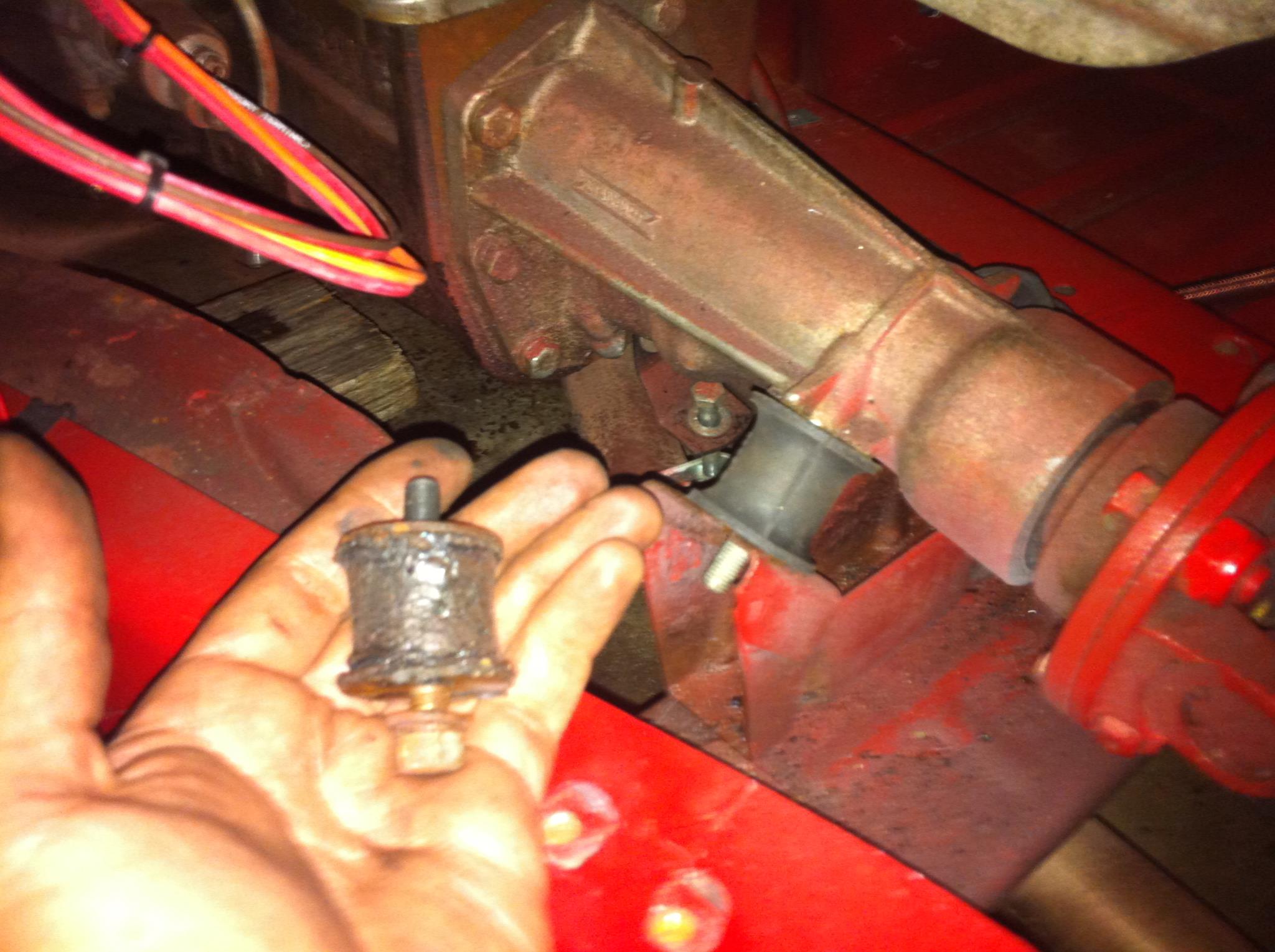

Whilst enjoying the delightful task of removing the oil pan, it became apparent that jacking the engine up a bit would be helpful, thanks in no small part to some less than generous clearances for the Spitfire’s oil pan bolts engineered in by a diabolical chap at British Leyland back in the day. In keeping with the Triumph Spitfire Restoration Onion Effect (wherein peeling off and exposing one layer of detritus reveals yet another), during that process I tangled with what remained of the motor mounts, and deemed them somewhat past their prime. So out came the floor jack again and…

Hell yeah: managed to replace the motor mounts without dropping the engine and trans on the floor! AND managed not to bugger up the “new” oil pan!

…while I was at it and things were all jacked up removed the rear trans mounts too – now can permanently (again, for the second time – so much for planning ahead!) cover this over with the new gearbox cover and carpet.

That Revolutionary War re-enactment I had with the Spitfire’s oil pan a few weeks back was not just for sport: it was part exploratory surgery and part triage to assess the condition of said oil pan. The verdict was not good. Fortunately, a call to the ever helpful chap at Spitbits yielded the part the even they (along with all other suppliers) didn’t list on their site: the mythic oil pan. Sure it was a trifle used, but not as used as the one on my Spitfire. The quasi-solidified, primordial oil-based muck at the bottom of this pan convinced me that the only way to really change the oil in this Spifire was to throw out the pan with the bathwater. (The old oil pan has since been convalescing in my retirement community for parts that will one day be refurbshed and ebay’d).

Pictured here, we’re 1/2 way thru a thorough (albeit messy) oil change (1st in over 10 years) process consisting of: unmounting the engine; jacking up engine; shoehorning old oil pan out from between bottom of block, top of frame crossmember & front of bellhousing.

Down under where the sun don’t shine on a triumph Spitfire – bottom of block flange cleaned & ready to meet the “new” oil pan.

Again turning to my factory manuals and cache of highly specialized British Leyland certified mechanic’s tools (or maybe just a couple cold ones), I’m hard at work locating & prepping to cut mounting holes for seats & seatbelts in new carpet for the Spitfire with an awl, 3″ roofing nails and chalk. Seems to work out fine, just the same.

The long and winding road of restoring and maintaining a 1974 Triumph Spitfire 1500